In leccción is

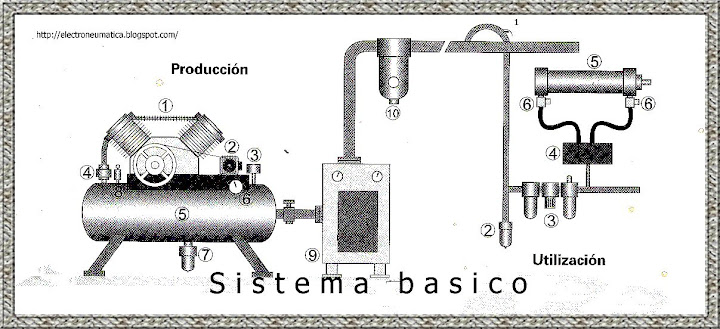

As you see in the picture, we must distinguish two parts in the system:

- Production and distribution of air.

- Utilization and air consumption.

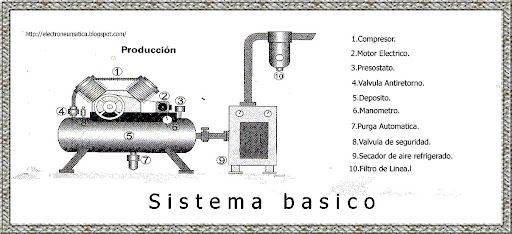

PRODUCTION SYSTEM OF AIR.

- Compressor. The air at ambient atmospheric pressure is compressed and delivered to maselevada pressure pneumatic system. It transforming the mechanical energy to air.

- electric motor. It provides the mechanical energy to ompresor. Transforms electrical energy into mechanical energy.

- switch. Controls the electric motor senses the pressure in the tank. It regulates the maximum pressure to a motor that tripped and minimum pressure at which the engine restarts.

- Valvla backstop. Lets the air compressor to the tank and prevents their return when the compressor is stopped.

- deposit. Air stores compressed. Its size is defined by the capacity of the compressor. The larger volume are longer intervals the compressor.

- Gauge. Indicates the pressure of the compressor.

- Automatic Purge. Purge all the water that condenses in the tank without needing supervision.

- Safety Valve. Expels air compressed if the pressures in the tank rises above the allowable pressure.

- Refrigerated Air Dryer. Compressed air cooled to a few degrees above the minimum pressure point and the ability to remove oil suspension.Sirve lubricant to keep the line free of dust, water and oil.

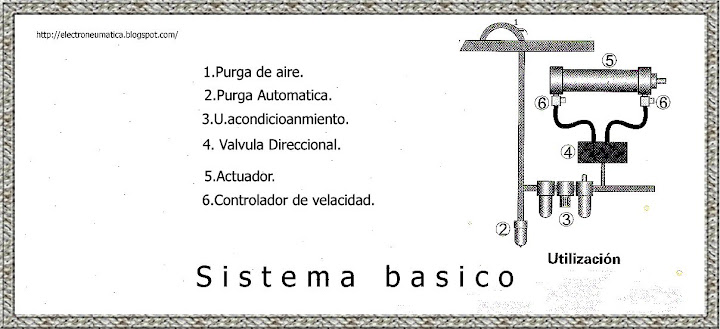

Utilization System.

- 1.Purga air. For ONSUMPTION, air is taken from the top of the water main to allow for occasional condensation remains in the water main, when it reaches a point low output uan stop water from the bottom of the wrath of a drain pipe thus eliminating automatic condensate.

- 2.Purga Automatica. Each tube offspring, should be a drain on their end inferior.El most effective method is an automatic drain prevents water stays in the tube in a case where neglect the manual purge.

- 3.Unidad air conditioning. Condition the compressed air to clean air supply at an optimum pressure and occasionally adds lubrication to extend the life of the tire sistena components that need lubrication.

- 5.Actuador . Delaire transforms potential energy compressed into mechanical work. The figure shows a linear cylinder, but may be a rotary actuator or a true tool air.

- 6.Controladres speed. Allow easy and continuous regulation.

In this lesson we learn that a system works and how fuionan neumaticobasico components.

RELATED POST.

- Pneumatic

- 2. Pneumatic

- 4.

Copyright © 2007-2008 [Electro Pneumatic]. All rights reserved.

Contact Form

0 comments:

Post a Comment